At the beginning of January, more than three hundred standards of interstate and national level came into force.

Among them are a series of documents on electromagnetic compatibility, standards for soils, gas boilers, and perfumes and cosmetics.

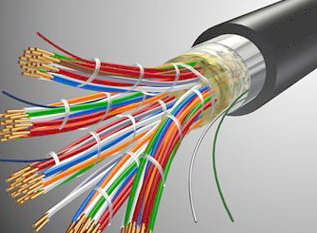

GOST 34679-2020, Block-signalling cables. General specifications. Cables covered by this document are intended for railway automatics and telemechanics devices; electrical signaling and interlocking installations of general industrial application; as well as for fire alarms and automatics. Their use assumes nominal AC voltage of 380 V at 50 Hz or 700 V DC. According to the type of conductive core design, such cables are subdivided into single-wire and multi-wire. Polyethylene or a halogen-free polymer composition is used for insulation of conductive cores. According to the standard, the core of cables must have a binding winding of synthetic filaments or tapes. There should be no dents, bubbles and cracks on the outer surface of the insulation.

GOST R 58324-2018, Suspended ceilings. General specifications. The document applies to modular suspended ceilings used as a finish for both new construction and renovation or repair. Depending on the material, the ceiling elements are divided into products of hard or soft mineral fiber, wood, metal or composite material. Ceiling structures, according to the standard, are classified into solid, which are mounted on the principle of "from wall to wall", and fragmentary, mounted by single pieces (solid and composite) or groups of single pieces. According to the text of the document the main indicators of quality ceiling elements are moisture resistance, sound absorption, light reflection, surface density, air permeability and thermal conductivity. In order to prevent heat from passing through a suspended ceiling structure, its elements must be at least 12 mm thick.

GOST R 58964-2020, Composite polymer mesh for reinforcement of masonry. Specifications. Composite polymer mesh (CPM) is used for reinforcement of horizontal joints of masonry bearing and non-bearing stand structures of buildings and constructions of various purposes. According to the type of continuous reinforcing filler in the rods, CPM are subdivided into glass fiber composite and basalt composite; by design - into braided and unbraided; by the shape of the finished product - into flat and coiled. According to the standard at manufacturing of CPM it is necessary to use binders on the basis of thermosetting resins. The content of continuous reinforcing filler in rods should be not less than 80% of the mass. All the rods of longitudinal and transverse direction should be connected in the area of 1 m2 in the CPM. The distance between the rods - the basic pitch of the rods in one direction should be taken the same. However, at the edges of the mesh, as well as at the point where it is cut, it is allowed to use a filler step. For longitudinal rods, the filler spacing is 25 mm to the size of the main spacing, multiple of 10 mm at the edge and multiple of 25 mm at the point where the mesh is cut. The filler step for the rods of transverse direction is from 25 mm to 250 mm, multiple of 25 mm.